Automatic Oil Burners series

Automatic Oil Burners series

AOH-M(E)

BASIC DESCRIPTION AND FUNCTION OF BURNERS

Burners AOH-M represent modernized type of automatic oil burner, intended for the burning of naphtha, light and extra-light fuel oils confirming with the standards ČSN 65 7991 and DIN 51 7991. Burner operation is fully automated, not demanding permanent attendance. Continuous control of heat output and low air excess within the burning guarantee high economy of the operation. From design point of view, the burner is designed as complex unit, i.e. the fan is directly in the body of the burner. Burners of the series AOH-M PL are equipped with oil heater, guaranteeing fast heating of the fuel to needed spraying temperature.

The whole cycle of burner from the start via output control to the shut-down is governed (after the impulse from operating sensors) by modern microprocessor automatics, equipped with communication channel RS-485, enabling the connection of remote control or superior control system (PC). The use of special algorithms enables the modification of control software such as f.e. extended period of venting after the termination of working cycle or permanent venting during the operating shut-down etc. Furthermore, the automatics enable f.e. the identification, representing and saving into the memory the case of 99 (resp. 50) last failure statuses and closing of the air suction at burner within each operating shut-down, thus reducing the stack loss occurring by the cold air flowing through consumer. The automatics can be located on the burner, to independent stand or into the panel of switch board.

APPLICATION

Oil burners serve as the source of heat for overpressure and underpressure consumers, especially for steam, hot-water and warm-water boilers. Nevertheless, they can be used also for another consumers with corresponding space for burning, not stressed by external fire (f.e. air heater, driers, steam generators, industrial and baking ovens etc.). The use for special technological purposes shall be discussed with producer.

OVERVIEW OF PRODUCED TYPES

AOH-M 04 PL, AOH-M 04 PNAOH-M 10 PL, AOH-M 10 PN

AOH-M 16 PL, AOH-M 16 PN

AOH-M 25 PL, AOH-M 25 PN

AOH-M 45 PL, AOH-M 45 PN

AOH-M 90 PL, AOH-M 90 PN

CONTROL

- continuous…continuous change of heat output according to immediate heat take-off

- two-step (three position)…MAX-MIN-SWITCHED-OFF

- manual operation…buttons directly on the automatics or by means of remote control, resp. superior control system

EMISSION

Burner operation complies in the full output range with the limits of hazardous emissions CO, NOx, SO2 and TL given by the government decree no. 146/2007 Coll.

Furthermore, burners can be also delivered with the control of residual oxygen in flue gases (f.e. Autoflame), balancing the activity of changing ambient conditions in the area of burners (oscillation of temperature and pressure of fuel and combustion air, change of stack traction...). Oxygen measurement probe together with special control equipment shall continuously correct the air excess in the flue gases, thus making the operation more effective with subsequent fuel saving.

BURNER DELIVERY

Basic scope of delivery includes the burner itself including microprocessor automatics and fuel filter, connection hoses and parts necessary for assembly. Option PL further includes fuel heater with control and emergency thermoregulator. Upon request, adaptor between burner and consumer can be delivered, output regulators, spare parts, or tailor-made products per demand. Guarantee period is 24 months from the date of sale, shall authorized service organization make putting into operation and adjustment.

SERVICE

Service of burners of PBS POWER EQUIPMENT, s.r.o. is guaranteed both by internal service department of the company and the network of contractual service partners.

technické parametry

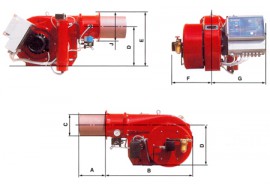

| Type of burner | Dimension (mm) | Inner diameter supply hose | Inner diameter reverse hose | ||||||||||

| A | B | C | D | E | F | G | J | K | L | N | |||

| AOH-M 04 P | 240 | 668 | ø 156 | 247 | 347 | 312 | 395 | 200x200 | 145 | 4 x M10 | ø 165 | DN 10 | DN 8 |

| AOH-M 10 P | 802 | ø 206 | 372 | 512 | 344 | 415 | ø 280 | 180 | 4 x M12 | ø 215 | |||

| AOH-M 16 P | 300 | 832 | ø 250 | 402 | 570 | 457 | 422 | ø 336 | 216 | ø 260 | |||

| AOH-M 25 P | 954 | ø 286 | 511 | 711 | 568 | 427 | ø 400 | 254 | 4 x M16 | ø 295 | DN 13 | DN 10 | |

| AOH-M 45 P | 1104 | ø 330 | 619 | 839 | 709 | 440 | ø 440 | 272 | ø 340 | ||||

|

AOH-M 90 P

|

400 |

1516

|

ø 476

|

864

|

1166

|

792

|

505

|

600

|

ø 540

|

6 x M20

|

ø 490

|

DN 15

|

DN 15

|

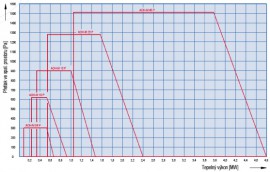

Basic technical parameters

|

Type of burner

|

Heat output (kW) | Max. over press. in comb. space (Pa) |

Fuel consumption (kg h-1) |

Max. inlet over press. of fuel (kPa) |

Inlet viscosity of fuel (mm2 s-1) |

Weight (kg) |

Voltage supply

|

El. input (kVA) | ||||

| Max. to zero over press. |

Max. to max. over press. |

Min. | With max. heat output to zero over press. |

With max. heat output to max. over press. |

Min | |||||||

|

AOH-M 04 PL

|

655 | 540 | 85 | 300 | 56,6 | 46 | 7,2 | 100 | 2 - 15 | 47 | Protected supply for electric motor 3 PEN alt. 50Hz, 230 V /400 V, TN-C-S |

2,55 |

|

AOH-M 04 PN

|

56,1 | 45,5 | 40 | 0,95 | ||||||||

|

AOH-M 10 PL

|

920 | 530 | 235 | 620 | 78,3 | 45,1 | 20 | 77 | 4,15 | |||

|

AOH-M 10 PN

|

77,6 | 44,7 | 19,8 | 65 | 1,15 | |||||||

|

AOH-M 16 PL

|

1475 | 1000 | 335 | 900 | 125,6 | 85,1 | 28,5 | 88 | 4,9 | |||

|

AOH-M 16 PN

|

124,4 | 84,3 | 28,2 | 75 | 1,9 | |||||||

|

AOH-M 25 PL

|

2400 | 1570 | 545 | 1280 | 204,3 | 133,6 | 46,4 | 120 | 5,6 | |||

|

AOH-M 25 PN

|

202,4 | 132,4 | 45,9 | 102 | 2,6 | |||||||

|

AOH-M 45 PL

|

5000 | 3775 | 1050 | 1510 | 408,5 | 321,3 | 89,4 | 246 | 14,9 | |||

|

AOH-M 45 PN

|

404,7 | 318,3 | 88,5 | 209 | 9,9 | |||||||

|

AOH-M 90 PL

|

8000 |

6900

|

2000

|

2000

|

680,8

|

587,3

|

170,3

|

490

|

17,9

|

|||

|

AOH-M 90 PN

|

674,5

|

581,8

|

168,6

|

475

|

12,9

|

|||||||

ke stažení