Automatic Combined Burners series

Automatic Combined Burners series

AKH – ME

BASIC DESCRIPTION AND FUNCTIONS OF THE BURNER

Series AKH-ME covers modernized types of automatic combined burners with power range from 400 into 8 000 kW for burning gaseous fuel (low-pressure and medium-pressure natur gas, propane, propane-butane, sewage gas, biogas, fire damp and extra light furnace oil (ELTO). Constructional are burner solving like monoblock, that ventilator air of combustion be contained directly in body of burner. Regulation quantity air of combustion is maked by mechanical regulation of air-flaps or with combination changes speed motor ventilator by means of inverter (savings electret. flow) and mechanical regulation of air-flaps.

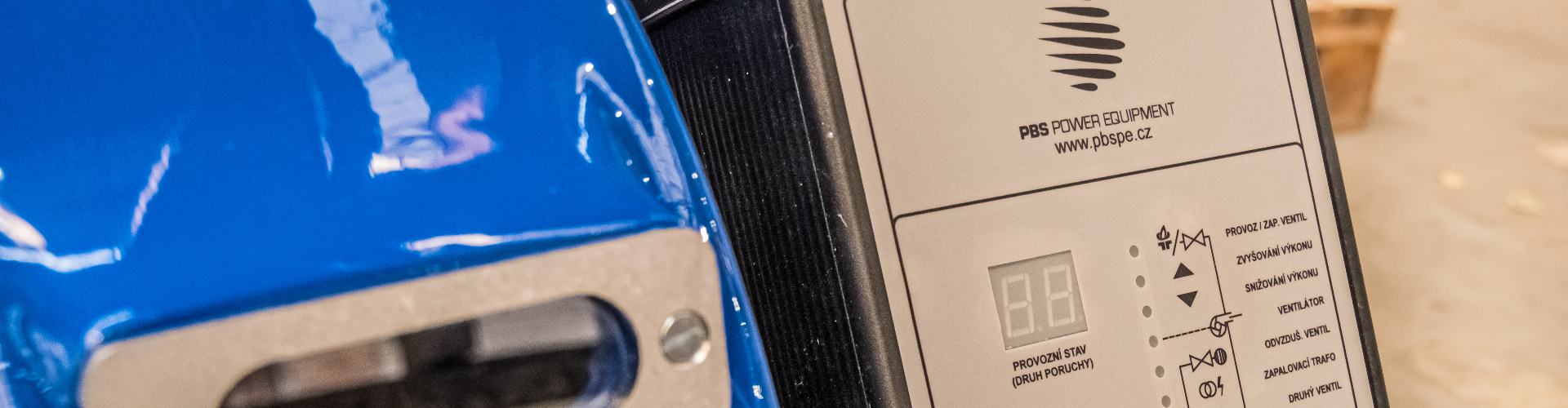

Burners are with burner controller PBS 6000 (electronic coupling fuel-air), what control starting cycle, check tightness of gas armature, regulation heat output and all interlocking function. Regulation of heat output burner can be automatic or hand-made from panel controller resp. up communication channel. With interface RS485 is possible watch operational state and control basic function of burner.On request is control system possibility add with O2 probe what continual watch and regulate balance air in burned gases for advance efficiency (decrease fuel consumption) whole combustion equipment.

Combined burners serve as the source of heat for overpressure and underpressure consumers, especially for steam, hot-water and warm-water boilers. Nevertheless, they can be used also for another consumers with corresponding space for burning, not stressed by external fire (f.e. air heater, driers, steam generators, industrial and baking ovens etc.). The use for special technological purposes shall be discussed with producer.

|

|

AKH-ME

|

|||

|

|

16

|

25

|

45

|

90

|

|

PZ+N

|

•

|

•

|

•

|

•

|

|

PZN+N

|

•

|

•

|

|

|

|

PP+N

|

•

|

•

|

•

|

•

|

|

PPN+N

|

•

|

•

|

•

|

|

|

PK+N

|

•

|

•

|

•

|

•

|

|

PKN+N

|

•

|

•

|

•

|

|

Legend marking:

PZ-natur gas, medium pressure

PZN-natur gas, low pressure

PP-propan-butan, medium pressure

PPN-propan-butan, low pressure

PK-sewage gas, biogas, fire damp, medium pressure

PKN-sewage gas, biogas, fire damp, low pressure

+N-extralight fuel oil (ELTO), resp. fuel diesel

Burner controller enables in connection with corresponding regulator of consumer following types of heat output control:

continuous - continuous change of heat output according to immediate heat take-off

two-step (three position) - MAX-MIN-SWITCHED-OFF

manual operation - buttons directly on the automatics or by means of remote control, resp. superior control system

EMISSION

Burner operation complies in the full output range with the limits of hazardous emissions CO, NOx, SO2 and TL given by the government decree no. 146/2007 Coll.

Basic scope of delivery includes the burner itself including microprocessor automatics and fuel filter, connection hoses and parts necessary for assembly. Upon request, adaptor between burner and consumer can be delivered, output regulators, spare parts, or tailor-made products per demand. Guarantee period is 24 months from the date of sale, shall authorized service organization make putting into operation and adjustment.

Service of burners of PBS POWER EQUIPMENT, s.r.o. is guaranteed both by internal service department of the company and the network of contractual service partners.

| Type of burner | Dimension (mm) | ||||||||

| A | B | C | D | E | F | H | K | L | |

| AKH-ME 16 | 833 | 880 | 588 | ø250 | 300 | 431 | 1039 | 216 | 4xM12 |

| AKH-ME 25 | 953 | 880 | 711 | ø286 | 300 | 443 | 1039 | 254 | 4xM16 |

| AKH-ME 45 | 1103 | 1040 | 839 | ø330 | 300 | 547 | 1039 | 272 | 4xM16 |

| AKH-ME 90 | 1516 | 1282 | 1166 | ø476 | 400 | 783 | 1039 | ø540 | 6xM20 |

BASIC TECHNICAL PARAMETERS FOR GAS

|

Type of burner

|

Max.

fuel inlet pressure (kPa) |

Heating output (kW)

|

Max.

over press. in comb. chamber (Pa) |

Connection

of gas feed type |

El. input (kVA)

|

Voltage

supply |

||

|

Max.

to zero- over pressure |

Max.

to max. pressure |

Min

|

||||||

|

AKH-ME 16 PZ

|

20 ÷ 50

|

1600

|

1000

|

320

|

1000

|

DN 50

|

1,4

|

Protected

supply for electric motor 3 PEN alt. 50 Hz, 400V /230 V, TN-C-S |

|

AKH-ME 16 PZN

|

2

|

1400

|

400

|

800

|

DN 80

|

|||

|

AKH-ME 16 PP

|

20

|

1500

|

900

|

DN 50

|

||||

|

AKH-ME 16 PPN

|

3

|

1400

|

950

|

|||||

|

AKH-ME 16 PK

|

20 ÷ 50

|

1500

|

1000

|

DN 80

|

||||

|

AKH-ME 16 PKN

|

1,5 ÷ 5

|

1300

|

300

|

800

|

DN 80 ÷ DN 100

|

|||

|

AKH-ME 25 PZ

|

20 ÷ 50

|

2600

|

1500

|

500

|

1600

|

DN 80

|

2,6

|

|

|

AKH-ME 25 PZN

|

2

|

2100

|

1700

|

580

|

650

|

DN 100

|

||

|

AKH-ME 25 PP

|

20

|

2500

|

1500

|

550

|

1500

|

DN 50

|

||

|

AKH-ME 45 PZ

|

20 ÷ 50

|

4800

|

3900

|

800

|

1430

|

DN 80 ÷ DN 100

|

6

|

|

|

AKH-ME 45 PZ/I

|

20 ÷ 50

|

5000

|

3700

|

1100

|

1700

|

8

|

||

|

AKH-ME 45 PP

|

20

|

4800

|

3900

|

1000

|

1400

|

DN 50 ÷ DN 80

|

6

|

|

|

AKH-ME 90 PZ

|

20 ÷ 50

|

8000

|

6900

|

1700

|

2000

|

DN 80 ÷ DN 150

|

11

|

|

|

AKH-ME 90 PP

|

20

|

DN 80 ÷ DN 100

|

||||||

BASIC TECHNICAL PARAMETERS FOR OIL

| Type of burner | Heating output (kW) | Max. over press. in comb. chamber (Pa) |

Fuel consumption (kg·h-1) | Max. fuel inlet press. (kPa) |

Fuel inlet viscosity (mm2·s-1) |

El. input (kVA) |

Voltage supply | ||||

| Max. to zero over press. |

Max. to over press |

Min | With max. heating output zero over press. |

With max. heating output max. over press. |

Min | ||||||

| AKH-ME 16 | 1475 | 1000 | 335 | 900 | 124,4 | 84,3 | 28,2 | 100 | 1,3÷20 | 1,9 | 3 PEN alt. 50 Hz 400V /230V |

| AKH-ME 25 | 2400 | 1570 | 545 | 1280 | 202,4 | 132,4 | 45,9 | 2,6 | |||

| AKH-ME 45 | 4800 | 3775 | 1050 | 1510 | 404,7 | 318,3 | 88,5 | 10 | |||

| AKH-ME 90 | 8000 | 6900 | 1700 | 2000 | 678 | 584 | 144 | 13 | |||