Residual gas burner

Residual gas burner

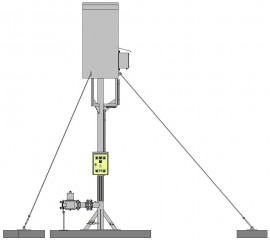

FLARE NTF

USE:

The PBS POWER EQUIPMENT, s.r.o. manufactures, installs and services atmospheric NTF type Flares used for combustion of residual biogas (resp. other combustible gas) mainly in cases of emergency stops of main consumers (cogeneration units).

INSTALLATION AND OPERATION REQUIREMENTS:

- placement 15 m from aboveground objects

- construction of a concrete foundation, a gas connection (main manual cutoff, filter), a fused electric energy connection, stops and M&R signals (incl. revisions)

- humidity free biogas (off-take behind the cooler, declined and corrosion proof ducts with draining in the lowest points on the line and before Flare)

Types - outputs:

NTF 80, 110, 260, 350, 500, 850, 1100 m3/h

FUEL - biogas:

- low pressure 5 kPa (±10 %)

- min. content 40 % CH4

In case of use of other gas or pressure ratios, it is necessary to consult the construction with the manufacturer.

STANDARD SCOPE OF DELIVERY:

- gas fittings (a solenoid valve with an end switch, a deflagrating safety device)

- a supporting column with a draining cock and a mixing nozzle

- a shell ("chimney") with combustion air control flaps, a flame monitor and ignition electrodes

- an electric box with the burner control automatics and an ignition transformer

- guys

- electric cabling

- technical documentation

ACCESSORIES PER ORDER:

- gas fittings (filter, manual cutoff, manometer ... )

- gas driven blower in Ex design with a frequency changer and a pressure sensor

- gas valve heating with a heating cable

- stabilization burner combusting propane or natural gas

The operation of Flare is fully automatic and requires no permanent service. Only occasional checks are required.

Flare NTF is a single-output burner with the option of the gas flow and combustion adjustment by qualified service. The adjustment is carried out by means of the ON - OFF system, while the gas consumption is defined by the time of combustion given by external signals (mainly percentage infilling or pressure ratios in the gas storage).

Combustion air is being sucked in from the ambient environment during the process of combustion in Fléra. The presence of flame is monitored with a flame monitoring device - ionization electrode.

The gas flow is controlled with a solenoid valve (with 2 valves for larger types) complying with the requirements of EN-161 and ATEX, and also with an end switch (monitoring the closing of the valve prior the start-up). The gas inlet is further equipped with an explosion deflagrating safety device.

Automatics placed in a separated electric box on the Flare supporting column controls the burner cycle and stops. It can be placed further from Fléra, out of the explosion risk zones area.

Basic technical parameters:

- amount of combusted residual biogas 80÷1100 m3/h

- 1NPE~ 50 Hz, 230 V/TN-S (or TN-C), electric input up to1 kW

- height 4,5 - 5 m